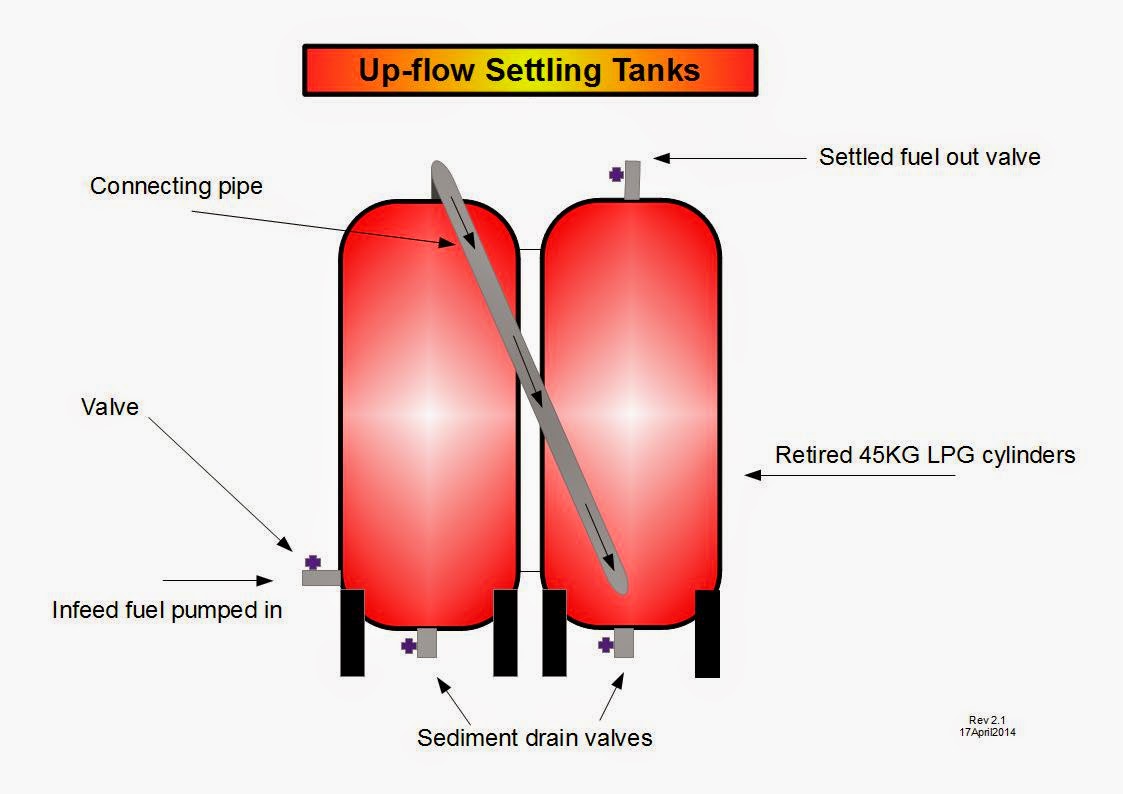

6April2016. Update: the Settler tank diagrams refers to the infeed inlet as fuel "pumped in". This is not really the case as such. Fuel enters at the speed of about 5L per day and is ultimately controlled by the drip rate at the exit. The is also a 20L header tank(not pictured). More info on the Upflow Settler page.

Cracking is essentially a high temperature treatment which breaks up heavier or larger hydrocarbon molecules into smaller ones, often at the same time altering their internal structure. There is not sufficient hydrogen in the large molecules to supply the needs of the small molecules into which they crack. The result is that heavier molecules are also formed at the same time. The total product of the cracking of a heavy oil contains gases, light hydrocarbons and hydrocarbons with large molecules, larger than the original oil as well as fractions boiling within the range of the oil which is being cracked.

Reflux Vessel

Reflux is a distillation technique involving the condensation of vapors and the return of this condensate to the system from which it originated. The DIYDiesel method separates diesel and lighter fractions, allowing these to proceed downstream from the reflux vessel, toward the condensers. Any heavier than diesel fractions condense in the reflux vessel and run back to the retort by gravity. This continuous recycling of heavy fractions till they are cracked to lighter diesel fractions goes on automatically. The temperature of the reflux vessel is a key critical setting which dictates the weight of the diesel produced.

A reflux temperature that is too high will produce a heavy diesel. Too low reflux temperature will produce light weight diesel, use more heat energy and take a longer time.

Currently 350°C is my reflux target. At the 380°C, there would be almost no refluxing going on, in other words you'd be getting out product at much the same weight you were putting in. The temperature is really a balance of a number of variables so each operator needs to be ready to adjust it to suit their particular conditions. Perhaps the most important criteria deciding the reflux target is the weight of product being produced.

Product produced too heavy: remedy = lower the reflux temperature.

Product produced too light: remedy = raise the reflux temperature.

Diesel Condenser Vessel

A the time of writing the Orion diesel condenser temperature target was 60°C because only the lightest, most volatile fractions that have low a boiling point are removed. These lighter fractions are condensed downstream in the gasoline condenser and used for other purposes. Keeping the diesel at 60°C and extracting the lighter fractions means it will be completely stable in a hot diesel engine. Also the temperature forces non-condensable gases downstream to the gas burner for creating retort heat.

Petrol/Gasoline Condenser Vessel

The petrol condenser vessel is directly downstream from the diesel condenser vessel and collects all that evaporates out of the diesel. This vessel target is at or below 20°C. The extra light weight fractions that evaporate at or below the 20°C mark will continue still further downstream and be used as heat in the burner, via the bubbler.

Cetane/Octane

Cetane is a rating for diesel and is a measure of spontaneous ignition for the fuel. Ideal would be a very low ignition resistance with higher numbers indicator better values. Octane is the opposite and inverse of cetane and is required in a spark ignition petrol engine. With octane, higher numbers are also denoting higher values.

Additives 2-ethylhexyl nitrate and di-tert-butyl peroxide are used as additives to raise the cetane number by fuel companies. I'm currently looking for an affordable supply of 2-ethylhexyl nitrate.

Carbon Chains of Typical Hydrocarbons

The graph shows the typical range of carbons in each product. What is important to realize is gasoline overlaps diesel. The chart shows gasoline with carbons in C4 - C12 range while diesel has C7 - C24. In this example C7, C8, C9, C10, C11 & C12 are part of both products!

So does this work ? Have you built it ?

ReplyDelete